Laboratory & Testing Capabilities

Ascona

Optical Technology: Uses high-resolution cameras to capture profile images.

High Accuracy: Provides high precision measurements, ensuring that the dimensions and shape of the profiles are within the specified tolerances.

Fast Analysis: Can analyze and check profiles in real time, reducing inspection time.

Quality Control: Ensuring that every extruded profile meets quality standards.

Dimensional Analysis: Measuring dimensions and checking shape to identify any deviations from specifications.

Reporting: Generating measurement reports for documentation and tracking.

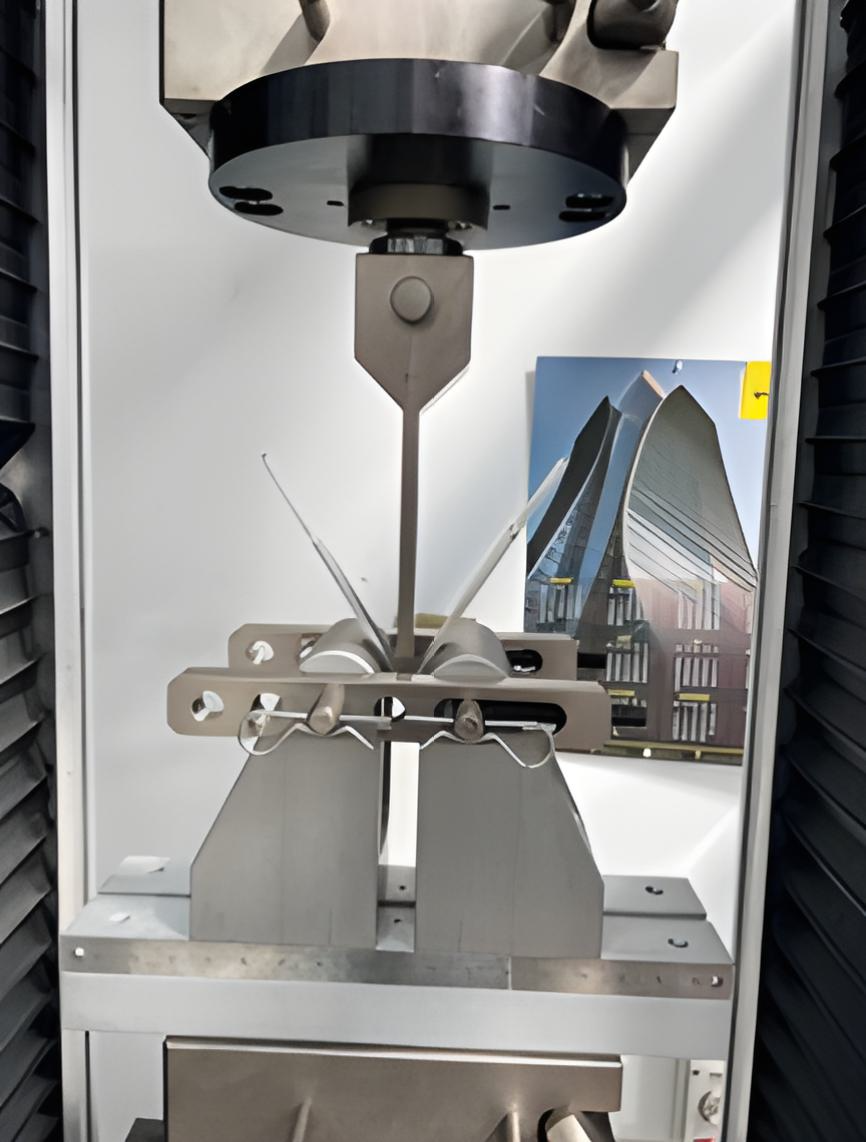

Ibertest

IBERTEST is a device that tests the mechanical analysis of aluminum components, including tensile and bending tests. Through this test we ensure the quality of the product by analyzing and graphically expressing the strength, extensibility and elasticity of the material.

Faro Arm

Faro Arm is a measuring tool (CMM) with which we perform 3D measurements for surfaces and complex components. In this way, we reduce time and increase efficiency in quality control processes. It is necessary for dimensional analysis of profiles and quality assurance.

Bend Test

Bend test performance is an essential part of our quality control process. This test helps us ensure that our materials are durable and safe to use by assessing their flexibility and resistance to deformation and strain. Through the bend test, we can identify materials with potential defects that can lead to structural failures and eliminate them from the manufacturing process. This helps prevent potential problems when customers use our products. Also, the bend test allows us to ensure that our products meet high quality standards and are within specified tolerances. This test provides us with valuable data to optimize our production processes, improving efficiency and reducing waste and costs. In this way, the bend test not only ensures the durability and performance of our products, but also improves the overall efficiency and effectiveness of production.

Hardness Tester

Hardness test is a specific machine to measure the resistance of materials. With this machine, we test the material at Rockwell & Brinell and determine the strength of the aluminum components. This test is necessary to evaluate the properties and quality of the aluminum we produce.

Compression & Crash Test

Performing the Flare Test is an essential part of our quality control process. This test is critical for several reasons: Flare Test helps us make sure our profiles are stable and safe to use. By evaluating the flexibility and resistance of materials to deformations, we can identify and eliminate defective materials that can lead to structural failures during their use. This test allows us to verify that the extruded profiles meet the required standards and are within the defined tolerances. Also, this test provides us with valuable data that helps us to optimize our production processes. This contributes to improving production efficiency and reducing waste and costs, making our process more efficient and sustainable. Testing aluminum profiles in the Everest Automotive industry is essential for ensuring safety, durability, performance, cost-effectiveness, regulatory compliance, and continuous innovation. We offer manufacturers high-quality parts, that means high-quality vehicles that meet customer expectations and regulatory requirements while staying competitive in the market.

Faro Arm

Faro Arm is a measuring tool (CMM) with which we perform 3D measurements for surfaces and complex components. In this way, we reduce time and increase efficiency in quality control processes. It is necessary for dimensional analysis of profiles and quality assurance.

Bend Test

Bend test performance is an essential part of our quality control process. This test helps us ensure that our materials are durable and safe to use by assessing their flexibility and resistance to deformation and strain. Through the bend test, we can identify materials with potential defects that can lead to structural failures and eliminate them from the manufacturing process. This helps prevent potential problems when customers use our products.

Also, the bend test allows us to ensure that our products meet high quality standards and are within specified tolerances. This test provides us with valuable data to optimize our production processes, improving efficiency and reducing waste and costs. In this way, the bend test not only ensures the durability and performance of our products, but also improves the overall efficiency and effectiveness of production.

Hardness Tester

Hardness test is a specific machine to measure the resistance of materials. With this machine, we test the material at Rockwell & Brunell and determine the strength of the aluminum components. This test is necessary to evaluate the properties and quality of the aluminum we produce.

Flare Test

Performing the Flare Test is an essential part of our quality control process. This test is critical for several reasons:

Flare Test helps us make sure our profiles are stable and safe to use. By evaluating the flexibility and resistance of materials to deformations, we can identify and eliminate defective materials that can lead to structural failures during their use. This test allows us to verify that the extruded profiles meet the required standards and are within the defined tolerances.

Also, this test provides us with valuable data that helps us to optimize our production processes. This contributes to improving production efficiency and reducing waste and costs, making our process more efficient and sustainable.

Testing aluminum profiles in the Everest Automotive industry is essential for ensuring safety, durability, performance, cost-effectiveness, regulatory compliance, and continuous innovation. We offer manufacturers high-quality parts, that means high-quality vehicles that meet customer expectations and regulatory requirements while staying competitive in the market.