Fabrication

Precision in aluminum machining is not just a goal, it's a necessity for unlocking its full potential

Our fabrication department is equipped with advanced machinery to ensure high-precision results. A key highlight is our CNC machining capabilities, featuring both 3-axis and 4-axis milling machines, including an upcoming Elumatec CNC machine with 18 axes for machining long profiles. This ensures precision in producing automotive parts such as structural members and panels. In addition, our facilities support various processes like welding, forming, and cutting, all designed to meet the highest standards of efficiency and quality.

Cutting

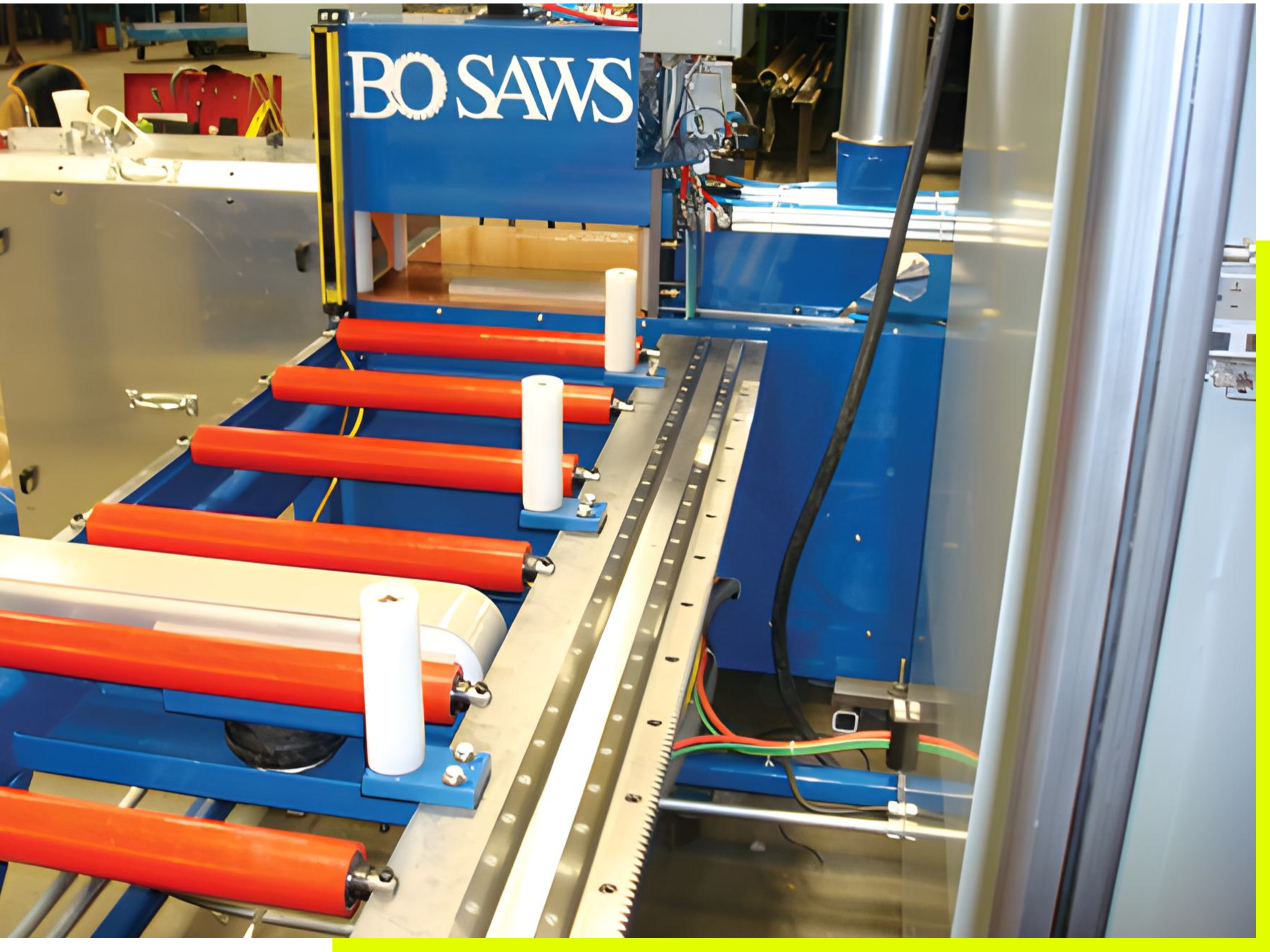

In our Saw Department, precision is our mantra. When it comes to slicing through aluminum, our operators are true masters of their craft. Equipped with razor-sharp blades and advanced cutting techniques, they slice through even the toughest materials with surgical accuracy. Each cut is made cleanly and precisely, ensuring components are perfectly prepared for the next stage of production.

Our cutting edge saw systems ensure accuracy and efficiency:

- EMMEGI

- B&O Saw

- ELUMATEC

CNC Machining

We manage both short and long-run productions, as well as prototypes. Many automotive parts, such as structural members, ribs, bolsters, and panels, are produced here.

We utilize a variety of milling processes, including 3-axis and 4-axis CNC milling machines, both upright and pendulum types.

The Doosan aluminium machining center accommodates components up to 2160 x 760 x 650 mm. After milling, parts are cleaned in a washing machine to remove cooling lubricants and impurities.

Additionally, we are proud to introduce a new Elumatec CNC machine with 18 axes, designed for high-precision machining of long profiles.

Key CNC Machines:

- ELUMATEC SBZ 628 XL X5

- ELUMATEC SBZ 628 S X2

- ELUMATEC DG 142 X4

Forming

We offer advanced bending (forming) services, including roller bending, which allows for the precise shaping of aluminum profiles. This process ensures that the components maintain their strength and integrity while meeting the required specifications. Our forming capabilities are designed to meet the high standards of the automotive industry, providing both efficiency and accuracy for every project.

Welding departament

In our Welding Department, technology is our ally. We embrace the latest advancements in welding equipment and techniques to push the boundaries of what's possible. With state-of-the-art welding machines that deliver flawless seams, we harness the power of technology to elevate our craft and deliver superior results.

The welding department, equipped with modern machines operated by a specialized workforce, utilizes various welding processes, including Metal Inert Gas (MIG) welding and TIG.